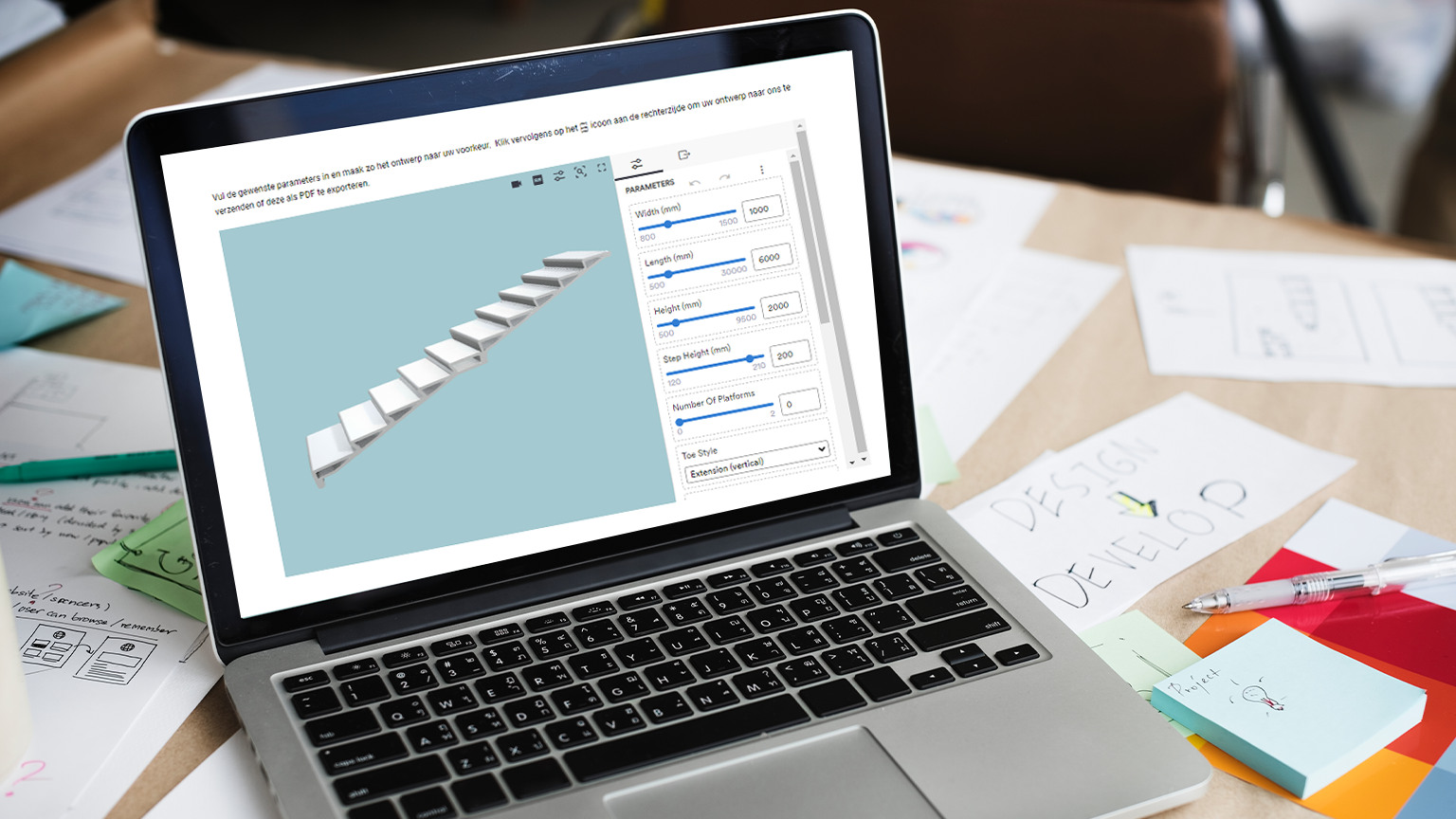

Further development of technology

The realisation of the first 3D printed house was followed by a lot of background hard work on further development of the printing technology. In recent years, Saint-Gobain Weber Beamix, with a branch at the Hurk business park in Eindhoven, has invested heavily in the development of the overall process in order to achieve a unique industrial and scalable 3D concrete printing process. Partly in cooperation with Eindhoven University of Technology (TU/e), this process has been developed and optimised in detail in recent years, resulting in continuous delivery of guaranteed quality. This requires less material compared to existing construction methods, thus saving on CO2.

New designs

Two new types of house have been developed that, unlike the first house, consist of several floors. The new houses derive their structural properties entirely from the printed concrete, a globally unique property within 3D printed housing construction. With their organic design – a habitable ‘boulder’ – the new houses are perfectly suited to their woodland settings. Two of each type of house will be located in Bosuil in Eindhoven.

Start of sale

Unlike the first house in Project Milestone, the new houses will be offered for sale. Interested parties can visit www.3dprintedhouse.nl where all the information about the 3D printed houses can be found and interested parties can contact us. Sales are scheduled to start after the summer holidays.

Realisation

After completion of the sales process, the realisation of the houses will begin in early 2025. Preparations for this are already in full swing. The plan is that the new residents will be able to move into the houses in the summer of 2025.

Working together with innovation

Characteristic of the Milestone project is the cooperation between government, knowledge institutions and the business community. The municipality of Eindhoven is a co-initiator, driver of innovation and facilitator of the project, the TU/e conducted research and developed models to make 3D concrete printing possible, Saint-Gobain Weber Beamix developed the process needed to deliver consistent quality on the production line, Houben / Van Mierlo Architecten designed the houses, Witteveen+Bos is working on the structural and engineering aspects and the construction company Van Wijnen is leading the project and building the houses.

Do you want to know more about Project Milestone or the possibilities of 3D concrete printing? Contact us then.

Curious about all the benefits?

Download our reference brochure

Do you want to visit one

of our 3D printing projects?