This 400 m² skatepark at Esplanade de Paris La Défense resembles a gigantic pinball machine and is accessible to everyone from July 18 to August 11 during the international sports competition. Beginners and experienced skateboarders, families, and people with or without disabilities are all welcome to experience the sport together.

Successful tests

Several skate elements were tested by prominent skaters and influencers in the 3D concrete printing factory in Eindhoven. The surface is perfectly suited for skateboarding, being neither too smooth nor too rough. “I can’t wait to explore the full skatepark and see how the riders make it their own,” says Hortense, co-founder of the Concrete Surf Riders Paris club. Haleksgang, a member of the O Labo club, is also positive: “Our test on the skate elements was really convincing. Saint-Gobain Weber Beamix got it right. We were able to talk with the developers and producers of the elements and gave them some finishing tips to optimize the riding experience as much as possible.”

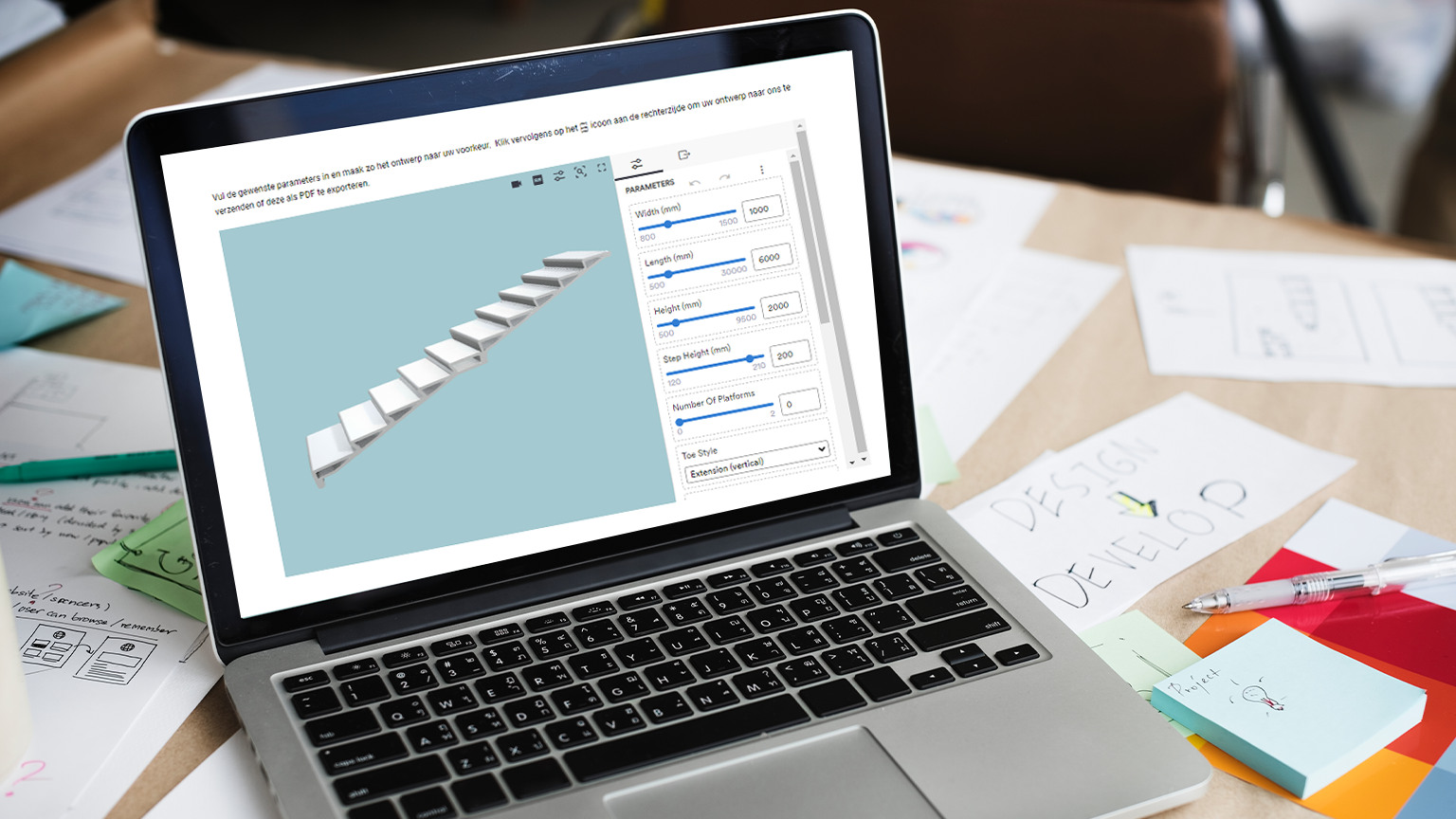

The advantages of 3D concrete printing

The 3D concrete printing technique offers several significant advantages over traditional production methods. Thanks to the 3D concrete printing technology, skate elements can be designed and produced with utmost precision. This makes it possible to realize unique and complex shapes that perfectly meet the needs of skateboarders and were not feasible with traditional formwork. This provides designers and architects the freedom to think beyond traditional boundaries and create unique, functional skate elements.

Moreover, the production of skate elements with 3D printing technology is significantly faster than traditional methods and this innovative technique results in a CO2 reduction of 40 to 60% compared to traditional constructions. This is because concrete is used only where necessary and no reinforcement is required in the construction.

“We are extremely honored to apply this revolutionary technology for this unique project that Saint-Gobain is realizing in the run-up to this major sports event,” says Peter Paul Cornelissen, 3D Business Unit Manager at Saint-Gobain Weber Beamix. “Our 3D printed skate elements will not only enhance the sports experience for the users of this skatepark but also demonstrate how advanced the technology in the construction sector has become.”

Curious about all the benefits?

Download our reference brochure

Do you want to visit one

of our 3D printing projects?